Buzzwords like "Smart Factory" or "Digital Twin" are currently all over the media and offer a variety of interesting approaches in the field of digital factory planning. From self-learning and self-communicating systems to autonomous maintenance, there is a multitude of potential application areas in every form and in a variety of industries.

The reality in most medium-sized companies speaks a different language. Factory planning is often understood as a one-time process, which is carried out in a structured manner during the creation, conversion or expansion of a company's own factory, and then evaporates in the day-to-day business. The generated results and data sets are usually not up to date and have different versions and formats for the respective use case, without being a complete whole.

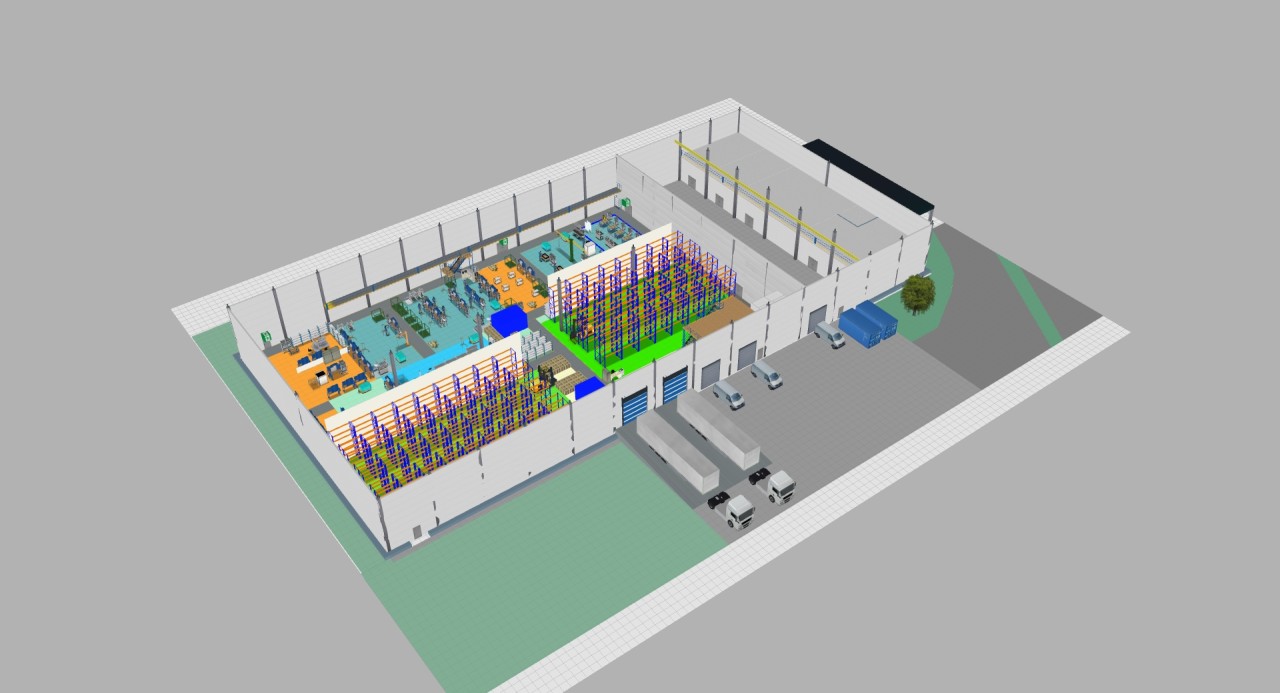

All factory planning activities should be understood as a continuous task in the company that enables synchronized value creation with the help of methods and tools, which can serve as the basis for entrepreneurial action.

The advancing digitalization offers a variety of software solutions that support the implementation of the described systematics and thereby significantly facilitate the entire factory planning process. Examples include the Vistable application or the mapping tool from NavVis. How these applications can bring a clear advantage in the daily business with manageable effort and investment, we want to publish here in a series of Insights over the coming weeks. You are also welcome to tell us about your experiences with potent solutions on the market or to give us feedback. We look forward to the upcoming discussions with you.