Our mission

We divided the core measures of our project into five steps:

1. Definition of a validation process according to OEM standard

2. Definition of processing steps in the remanufacturing process and tolerance behaviour of the individual products

3. Technical product/process analyses and specifications for remanufacturing

4. Coordination of testing and cleaning processes for each motor type

5. Further development of the validation and release process on the basis of new technical methods and standards

Our work

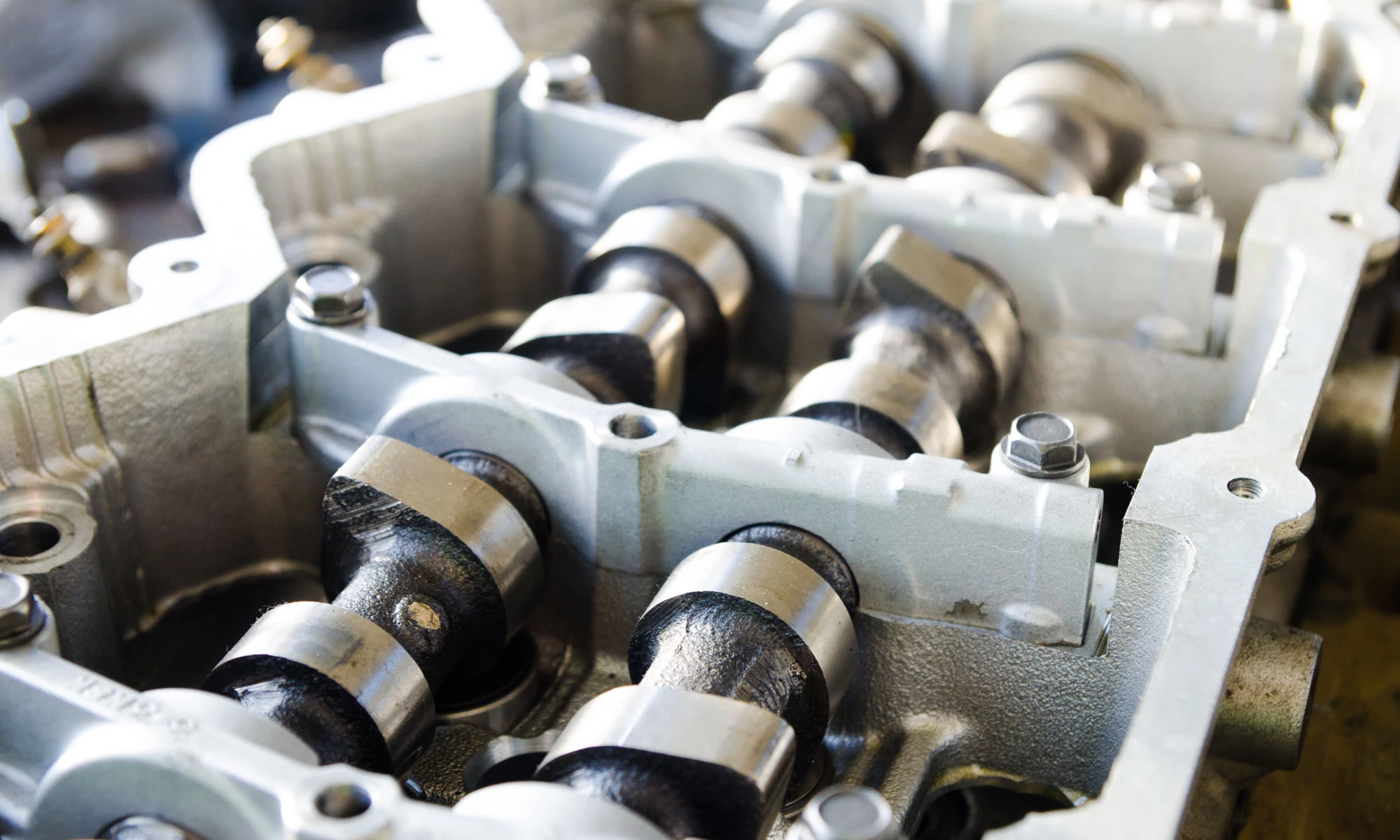

In detail, our experts started by coordinating the coverage for a defined portfolio of replacement engines for our customer in the automotive industry. In the next step we carried out the examination of the individual components and a precise definition of the processing steps and measuring points. This also included the planned component measurement and the subsequent targeted evaluation of the measurement results. In addition, technical specifications for the remanufacturing process were drawn up. The support of assembly processes with the subsequent assurance of component compatibility was also necessary for the success of the project. Our experts interpreted the results and then prepared detailed final reports. It was important to consider the individual departments, especially the coordination with the development and quality departments as well as the suppliers.

Our results

We were able to achieve the project goal by documenting the released engine types with a parts list at part number level. Approved individual components with extended “functional tolerances” provided additional information. Our experts developed a secure assembly process at component level as well as secure engine series for a series process according to OEM quality standards.

Our know-how

In this project, we benefited from a pronounced understanding of processes in the automotive OEM sector and the targeted use of our network. Comprehensive technical knowledge of the engine and engine peripherals also played a decisive role – in-depth knowledge of the effect of tolerances on functionality was another milestone in the project. Consistent methodology in the documentation and a professional presentation of results led to a secure project conclusion.

Our added value for the customer

A professional implementation by our experts led to the successful completion of the project. Engine types were approved and we were able to generate technical aftersales validation competence. We ensured the aftersales capability as well as the OEM spare part quality required for the project. A transparent presentation of the decision ultimately led to a quick result and thus to the necessary relief of internal resources.