Our mission

The objective of our work was on the one hand the planning and realisation of a car wash and on the other hand the implementation of a water treatment plant for the production of water with less than 10 % residual pollution. The focus here was on safety for the workers in the upstream and downstream areas of the washing plant as well as in the complex filtration plant.

Furthermore, the implementation of the independently developed technical solution was on the agenda. This work step should be carried out with the support of suppliers in compliance with the specified financial, time and technical framework conditions. The focus of the water treatment was on a good user-friendliness as well as a design of the plant with regard to minimum maintenance.

Subsequently, a solution had to be found to transport the vehicles through the car wash in a way that was safe for people and materials. The consideration of an extra secured area for the provision and takeover of the vehicle before and after the car wash was important.

Our work

Our team of experts carried out the following four work steps professionally for the client:

1. concept development under consideration of all interface partners

2. drawing up a specification, drawing up a list of bidders, evaluating the bids and recommending the order to the purchasing department

3. support of the supplier during the design phase, manufacture, implementation and commissioning of the equipment up to the final acceptance by the customer

4. competence build-up for the local supplier as well as the local planning organization regarding the project phases and project work to be carried out in the automotive industry.

Our results

The tender was based on a concept agreed with the department.

We prepared a supplier evaluation as the basis for the order recommendation for purchasing. In this context, several local car wash suppliers were visited and evaluated according to various technical and commercial aspects. A detailed design discussion including maintenance, production, building services engineering and occupational safety was decisive for the project’s progress.

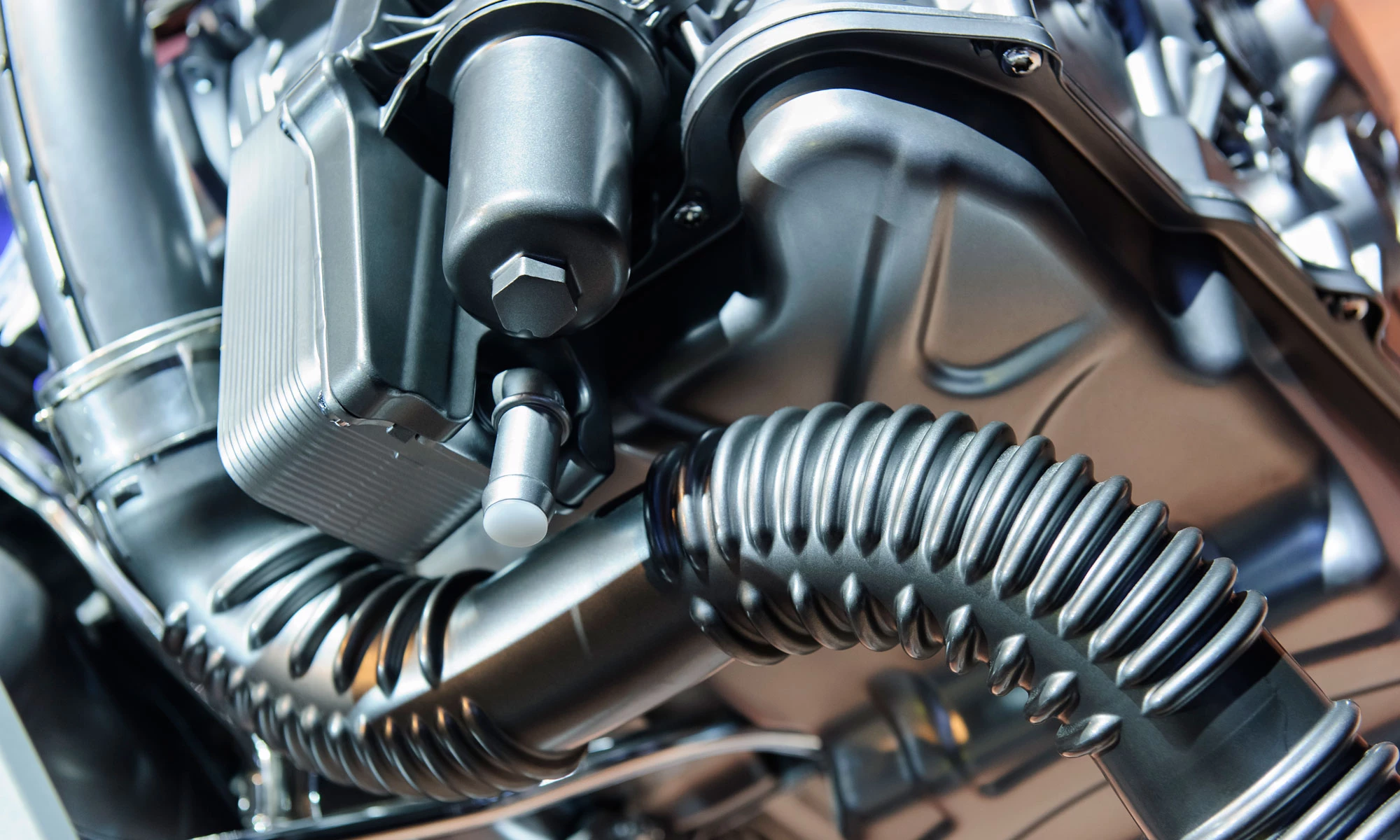

As a safety measure, regular inspections of production were carried out. This related on the one hand to the individual components of the washing line and on the other hand to the individual elements of the complex filtration system for water treatment. A preacceptance test was carried out under consideration of real conditions in the production operation. The inspection of the production of all components at regular intervals was an important milestone of the order.

In particular, the timeline had to be adhered to and the implementation monitored on an ongoing basis – countermeasures were taken in the event of a delay The team reported regularly on the progress of the project to the customer.

The customer's participation in project rounds to ensure that changes made by the customer were incorporated into the project flow was also adhered to. A well-prepared planning of all project steps including the acceptance of the equipment and handover to the operator was the basis for a constructive implementation of the project.

Our know-how

We use our industry know-how about the project process in general and the automotive industry in particular.

The knowledge of the supplier pool supplying the equipment as well as a technical understanding of the equipment to be implemented was a good prerequisite for the project. We use our international network to coordinate the German and Chinese suppliers involved in the project with regard to common interfaces, implementation and commissioning of the overall network. We used our special knowledge of the given industrial and customer-specific technical standards to ensure fast and reliable project progress. In our project work we bring with us an understanding of the customer-specific course of the project with all relevant milestones and specifications. We use knowledge transfer properties professionally within the framework of the required competence development. In this way we were able to achieve a tailor-made solution for our customer.

Our added value for the customer

In this project, too, we were able to complete the entire package step by step on our own responsibility. The previously fixed time and financial framework was adhered to. The successful build-up of competence of the local staff at the customer and the build-up of competence of future local suppliers will have a positive effect on project implementation in China in the future. We were able to meet the specified industrial and customer-specific standards. In addition, we were able to exceed the original requirements in terms of the quality, safety and functionality of the equipment. We created sustainable changes by optimizing the washing process: Reduction of the originally planned amount of water by 40 % compared to comparable systems. A continuous project documentation with final handover of all documents relevant for the operation of the plant secured the result.