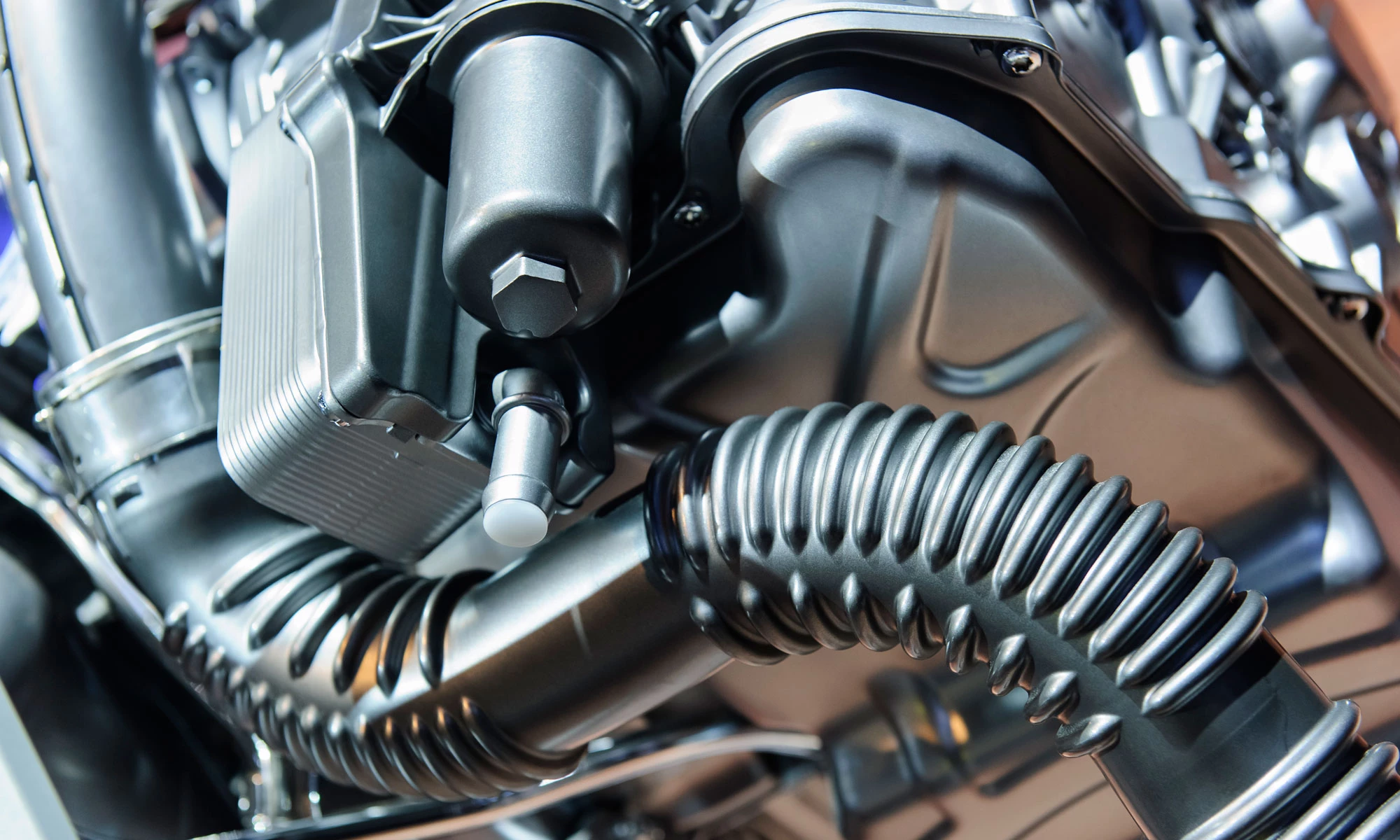

Practical example “reconditioned oil pump”.

The sustainable automotive manufacturer commissioned the MCG Technical Product Management division to coordinate the reconditioning of the aforementioned vane cell oil pumps in order to fulfil the spare parts supply obligation according to EOP (End of Production) and the sustainable parts chain. The challenge here was first to analyse the functioning of this pump and then to define the parts to be reused and replaced.

Due to the rejection of the producing Tier One supplier, only sporadic development data, drawings and material identifications were available, as the automobile manufacturer purchases the oil pump as a purchased part. Without this database, it is extremely difficult to reproduce the parts to be replaced in terms of durability and ageing resistance within the pump. This challenge, however, does not only arise in the recycling of oil pumps, but also in every functional component within the periphery of an engine or drive train and also within the auxiliary units.

Approach Technical Product Management

The approach was an empirical one. The sealing strips within the oil pump that were not available and had to be replaced had to be measured with the help of a partner so that a CAD data set could be created. This data set was then used for the production of injection moulds. At the same time, a material analysis was commissioned in order to guarantee the same standard of material, durability and ageing resistance as the original. The remaining components of the oil pump were also measured by a partner, evaluated by the Technical Product Management team and then compiled in a sorting matrix in order to obtain pumps with extreme positions within the tolerance ranges.

The “Worst Case” pumps were secured and approved by means of endurance tests on the test bench. This special procedure is managed and documented by experts from Munich Consulting Group and then presented and handed over to the client in a final report.